WHEN YOU'RE

BUILDING THE FUTURE…

Your days are filled with critical decisions, change orders, and tight deadlines. To coordinate all the logistics involved, you rely on your radio. Yet every time you get shaken–travelling on rugged terrain or

using a forklift, digger or crane–you risk cutting off your crucial communications by damaging your radio battery with harmful vibrations.

Not so with Motorola.

Motorola builds radio batteries to withstand rigorous shaking. Then they prove it by running them through 12 strenuous hours of vibration. So no matter how jarring your work is their performance remains unshakeable.

TOUGHER THAN THE REST

IN THE VIBRATION TEST

A construction crew jack hammering a road. A maintenance worker handling heavy equipment. Engine 36 racing to a structure fire. Whether you place it on the seat or put it on a belt, one thing is certain: every radio gets shaken, repeatedly. Will it work when you pick it up? Is the battery tough enough?

TEST PROCEDURE

The Method:

Using the same test set-up the U.S. military does for its equipment (MIL810F Method 514.5), each battery was tested for its ability to withstand sine vibration (regular, repeating pattern) and random vibration – for a total of 12 hours.

Sine vibration (a regular, repeating pattern):

- 3 hours along the vertical axis

- 3 hours along the horizontal axis

- 3 hours along the perpendicular horizontal axis

Random vibration (no predictable pattern):

- 1 hour along the vertical axis

- 1 hour along the horizontal axis

- 1 hour along the perpendicular horizontal axis

The Inspection:

The batteries are inspected after each axis of vibration and failed if they experienced the following problems:

- Cracking or splitting open

- Damage to the connection with the radio

- Inability to charge

PASS /FAIL CRITERIA

Each battery was inspected and failed if they experienced the following problems: cracking or splitting open, damage to the radio connection, an inability to charge or a failure to discharge.

RESULTS

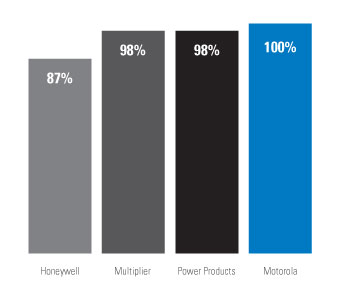

100% of Motorola batteries passed the test.

Broken latches and failure to provide power weere the major causes of failure

|